Spiral plate heat exchanger is a highly efficient heat exchanger equipment for steam - steam, gas - liquid, liquid - liquid, the liquid heat transfer. It is suitable for chemical, oil, solvents, pharmaceuticals, food, light industry, textile, metallurgy, steel rolling, coking and other industries. According to the structure can be divided into non-split type (Ⅰ type) spiral plate and removable (Ⅱ type, Ⅲ type) spiral plate heat exchanger.

Spiral plate heat exchanger using proven through years of practice, is indeed a

highly efficient heat transfer equipment, it applies to chemical, oil, solvents,

pharmaceuticals, food, light industry, textile, metallurgy, steel rolling,

coking and other industry applications. Draw contemporary international advanced

heat exchanger technology, the unique optimal design and manufacture of liquid -

liquid, steam - water heat exchanger. Product structure according to Swedish

technology, "Al Farah generation" company standards, end-use fold spiral plate

welding, "top from the column" special process for the charge storage capacitor

contactor, to improve the quality of the inner and outer "Baosteel" recognized,

can replace imports.

Can not be demolished by the spiral plate heat

exchanger is - Mechanized Division Standard JB/TQ724-89 can not be demolished

spiral plate heat exchanger in the form, the basic parameters and dimensions of

the design requirements, it has made a simple, low cost, small size and heat

transfer performance, etc., but also has its shortcomings, for example, can not

be machine washed, broken easy maintenance, etc., selection should be based on

the actual situation of the project specific selection of equipment to make the

most effective.

Structure and Performance

1, the device applies to:

liquid - liquid, gas - gas, gas - liquid convective heat transfer fluid can be

used for steam condensation and evaporation heat transfer, chemical, petroleum,

pharmaceutical, mechanical, electrical, light industry and textile industry can

be use.

2, this device is made by the two steel rolling, forming two

uniform spiral channel, two kinds of heat transfer can be full cut-off

counter-current flow for a small temperature difference between heat transfer,

easy and accurate recovery of low temperature heat source to control the outlet

temperature .

3, the shell is cut to a receiver on the structure of local

resistance is small, the curvature of the spiral channel is uniform, the fluid

flow in the device no major change to the total resistance, which can improve

the design flow so that with more high heat transfer capacity.

4, the

spiral channel ends are welded seal, sealing performance and reliable

structure.

5, is not easy to repair, especially when problems arise

within the board is extremely difficult to repair, some plant Weld the ends of

all the cars off the device and re-welding the plate and then roll flattening,

this consumption of working hours too, because selection spiral plate heat

exchanger corrosion is very important.

6, can not be machine washed,

production proven, and the general spiral plate heat exchanger tube heat

exchanger is not easy compared to plug, especially sand, shells and other small

suspended particles in the spiral channel impurity deposition is not easy,

analysis of the reasons; first, because it is a single impurity in the

deposition of a channel forming stream flow will also be increased to flush it,

the second accident because there are no dead ends spiral channel, impurities

likely to be out.

7, because the spiral channel with fixed channel

spacing from the support column, not a rejection of the fibrous impurities

(cotton, grass and sticks, leaves, etc.) into the heat exchanger inside.

8, the strict control of the cooling water outlet temperature in the temperature

scale below.

9, a common cleaning method is to use the net or caustic

steam blowing, blowing steam to take over, blow out the impurities from within

the device, many use the factory that this is an effective way.

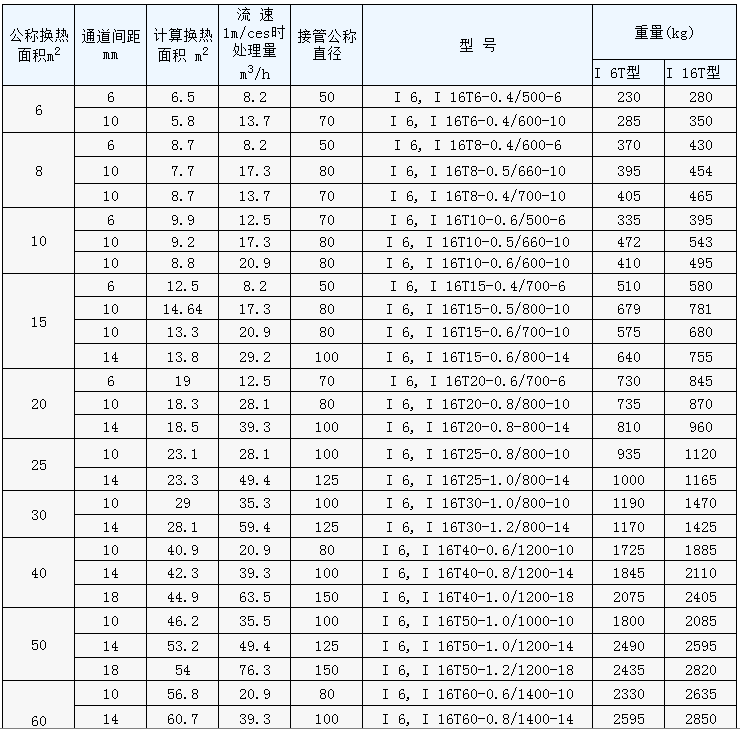

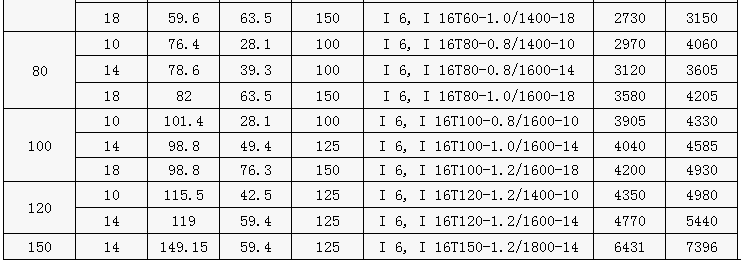

Detachable (Ⅱ

type, Ⅲ type) spiral plate heat exchanger

Principle and structure can not

be demolished heat exchanger is basically the same, but can open channel

cleaning, sealed at both ends of the first seal. Especially for sticky, with

precipitation of liquid and liquid-liquid exchange, and gas-liquid, vapor

condensation. As the need to add a removable heat exchanger head, flange and

other components, equipment costs than larger heat exchanger can not be

removed.

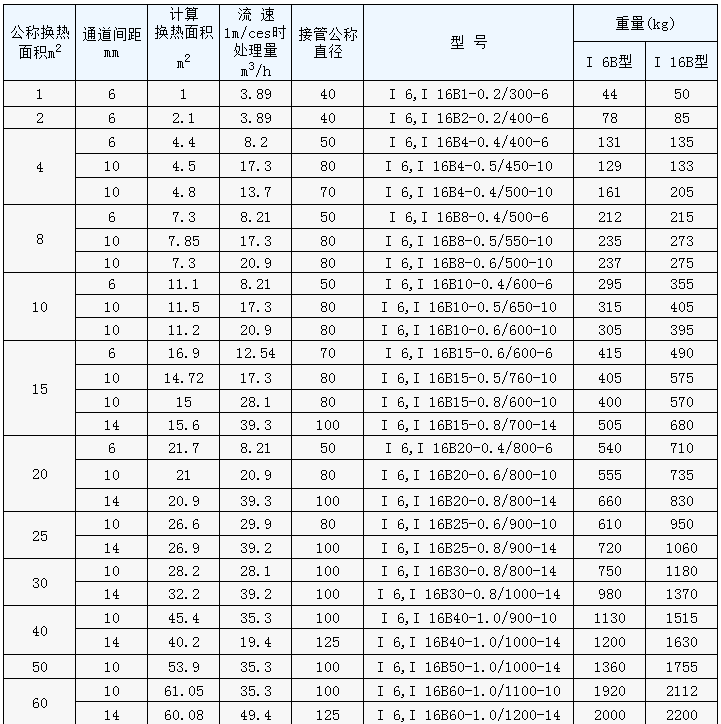

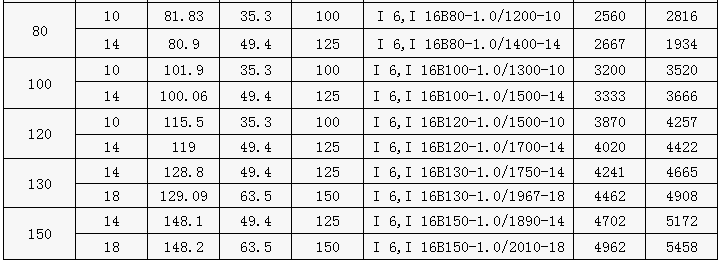

Basic parameters

Spiral plate heat exchanger Nominal pressure

PN defined as 0.6,1,1.6,2.5 Mpa (ie the original 6,10,16,25 kg/cm2) (refers to

single-channel with the maximum working pressure) test pressure for the working

pressure of 1.25 times.

Spiral plate heat exchanger and the media access

part of the material, carbon steel for the Q235A, Q235AF, stainless steel acid

as SUS321, SUS304. Other materials can be selected according to user

requirements.

Permissible operating temperature: carbon steel, t = 0 ~

+350 ℃, stainless steel, acid t =- 40 ~ 500 ℃, temperature step-down range of

pressure vessels according to the relevant provisions. Use this equipment,

contact should be through the process when the calculation of fluid within the

device channel to reach the turbulent state. (Usually gas flow rate of liquid

flow rate 1m/Sec 10m/Sec).

Single piece of equipment can not meet the

requirements, you can use more than one combination, but the combination must

meet the following requirements:

Parallel combination of series

combination: the same equipment and channel spacing. Hybrid combination of: a

parallel channel, a channel in series.

Acid-resistant stainless steel PN0.6, 1.6MPa can not be demolished (Ⅰ type) spiral plate heat exchanger.